For that, I am getting an antec power supply. I am getting the 400watt 2 axis kit but not getting their power supply modules. They have 2 axis kits that have everything from the servos, cables, drives, emergency stop switch, limit switches(to stop the machine from crashing and set zero) etc. 75kw servos are overkill and can snap a 1/2" carbide end mill or move my head on the mill(250+lbs) without issue.

I have 3 on my PM45m and have run it for 8-10 hours continuously without issues cutting stuff. They are quiet, extremely smooth and very strong. CNC axis motors- I am going with DMM-Tech 2 axis servo motor setup. I am putting together a comprehensive list but here is the broad strokes:ġ. Next up, I have timing pulleys coming and a 3 hp extreme duty motor already to go: the new carbide blade didn't flinch cutting a 5" deep cut 13" tall. I can't even begin to describe how much more rigid everything is with no compound and a giant piece of 7075 on the x axis.īTW, I cut the 7075 aluminum 13" tall with my Agazzani vertical bandsaw.

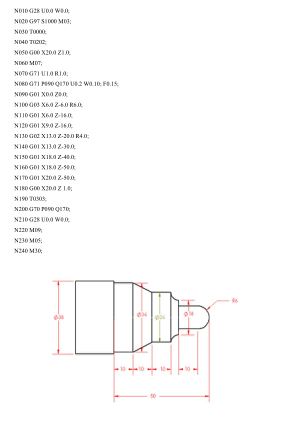

I was a little concerned whether having the ballscrew mounted offset would cause binding but after everything was mounted, a small cordless drill easily moves the x axis really well. I made ballnut mount via cnc on the mill: This setup took several hours to get it aligned but I was able to use it to flatten the saddle and also drill the holes to mount the ballscrew: Next I had to machine the saddle to make where I would mount the ballscrew perfectly parallel to the surface on the dovetail. It will replace the compound and shelter the ballscrew from shards etc and be a rigid platform for a turret or gang setup. I was able to pick up a 2.5"x 10" x 13" piece of 7075 tooling plate from the scrap pile at industrial metal supply. The servo will go underneath with timing gears to run it. There is no reason to have cranks and they just get in the way. All of this goes away with a cnc conversion and I will use a pendant to control it. I started by taking off the lead screws, x axis compound etc off. Instead, I am converting it to a gang or turret style cnc lathe with vfd and controlled by Mach 3. My Jet mill suffered another crash last year and completely lost threading capabilities on what was a decent machine.

#MACH3 LATHE MANUAL SOFTWARE#

I have gotten pretty good with Mach 3 software to control the mill and they have a suite of tools for the lathe that includes threading, drilling profiling and I am really looking forward to this even more than the mill. I am basically building off of the lessons learned from successfully converting my PM45M mill to CNC. and I hope it will be of help to anyone considering it. Most of this should translate to similar size lathes like the PM lathes etc. I wanted to start a new thread to document conversion of my Jet 13x40 lathe.

0 kommentar(er)

0 kommentar(er)